No products

View larger

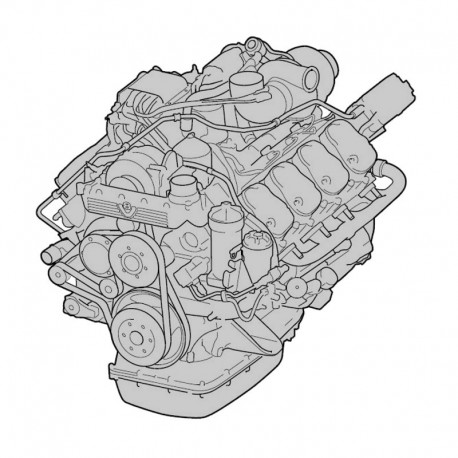

View larger Scania DC16 XPI - Inspection , Operator, and Workshop Manual

English Inspection , Operator, and Workshop Manual, to engines Scania DC16 XPI.

--------- INSTANT DOWNLOAD ---------

LANGUAGE: English.

FORMAT: PDF file

PAGES: 119

VALID FOR: Windows, Mac, Android and iOS.

PRINTABLE: Yes

Digital product, sent to email.

More info

SCANIA DC16 XPI ENGINES - SERVICE MANUAL

- English Inspection , Operator, and Workshop Manual, to engines Scania DC16 XPI.

INDEX:

INSPECTION MANUAL

- E2011

- Inspection

-- Engines with few hours of operation

-- Inspection intervals

- Lubrication system

-- Oil grade

-- Oil analysis

-- Checking the oil level

-- Changing the oil

-- Renewing the oil filter

-- Labels for top-up engine oil grade

-- Parts

-- Cleaning the centrifugal oil cleaner

-- Operational testing

- Cooling system

-- Coolant

-- Checking the coolant level

-- Checking antifreeze and corrosion inhibitor

-- Antifreeze and corrosion inhibitor

-- Changing coolant

-- Cleaning the cooling system

- Air cleaner

-- Reading the vacuum indicator

-- Renewing the filter element

-- Renewing the safety cartridge

- Fuel system

-- Checking the fuel level

-- Renewing the fuel filter

-- Renewing the water separating fuel filter

-- Bleeding the fuel system

- Miscellaneous

-- Checking the drive belt

-- Checking for leaks

-- Checking and adjusting the valve clearances and unit injector rocker arms

SERVICE & OPERATOR MANUAL

- Start-up Report – Warranty

- Introduction

- Environment and safety

-- Environmental responsibility

-- Safety

-- Warnings and advisories

-- Certification

- Scania engines engine warranty for industrial engines

-- Emission control systems warranty

-- Emission control system warranty statement

- California emission control warranty statement

-- Your warranty rights and obligations

-- Manufacturer's warranty coverage

-- Owner's warranty responsibilities

- SCR catalytic converter

- Engine data plate

- Component identification

-- SCR system

- Starting and running

-- Checks before running

-- Reductant pump

-- Starting the engine

-- Running

-- Engine shutdown

-- Checks after running

- Maintenance

-- Engines with few hours of operation

-- Cleaning the engine

-- Maintenance intervals

- Lubrication system

-- Oil grade

-- Oil analysis

-- Checking oil level

-- Changing the oil

-- Labels for top-up engine oil grade

-- Parts

-- Cleaning the centrifugal oil cleaner

-- Operational testing

-- Renewing the oil filter

- Cooling system

-- Coolant

-- Checking coolant level

-- Checking antifreeze and corrosion inhibitor

-- Antifreeze and corrosion inhibitor

-- Changing coolant

-- Cleaning the cooling system

- Air cleaner

-- Reading the vacuum indicator

-- Renewing the filter element

-- Renewing the safety cartridge

- Fuel system

-- Checking fuel level

-- Renewing the fuel filter using a bleeding tool

-- Bleeding the fuel system using a bleeding tool

- Miscellaneous

-- Checking the drive belt

-- Checking for leaks

-- Checking and adjusting the valve clearance

-- Renewing the reductant filter

-- Cleaning the reductant tank filler filter

-- Cleaning the reductant tank ventilation filter

- Diesel

-- Composition of the fuel

-- Sulphur content of fuel

-- Temperature dependency of the fuel

-- Biodiesel (FAME)

-- Use of fuel oil in stand-by generator sets

- Reductant for SCR

-- Responsibility and quality requirements

-- Properties

- Preparing the engine for storage

-- Handling the engine

-- Preservative coolant

-- Preservative fuel

-- Preservative oil

-- Preparations for storage

- Technical data

-- General data

-- Lubrication system

-- Injection system

-- Cooling system

-- Intake system

-- Electrical system

- Scania Assistance